Cartridge Heater

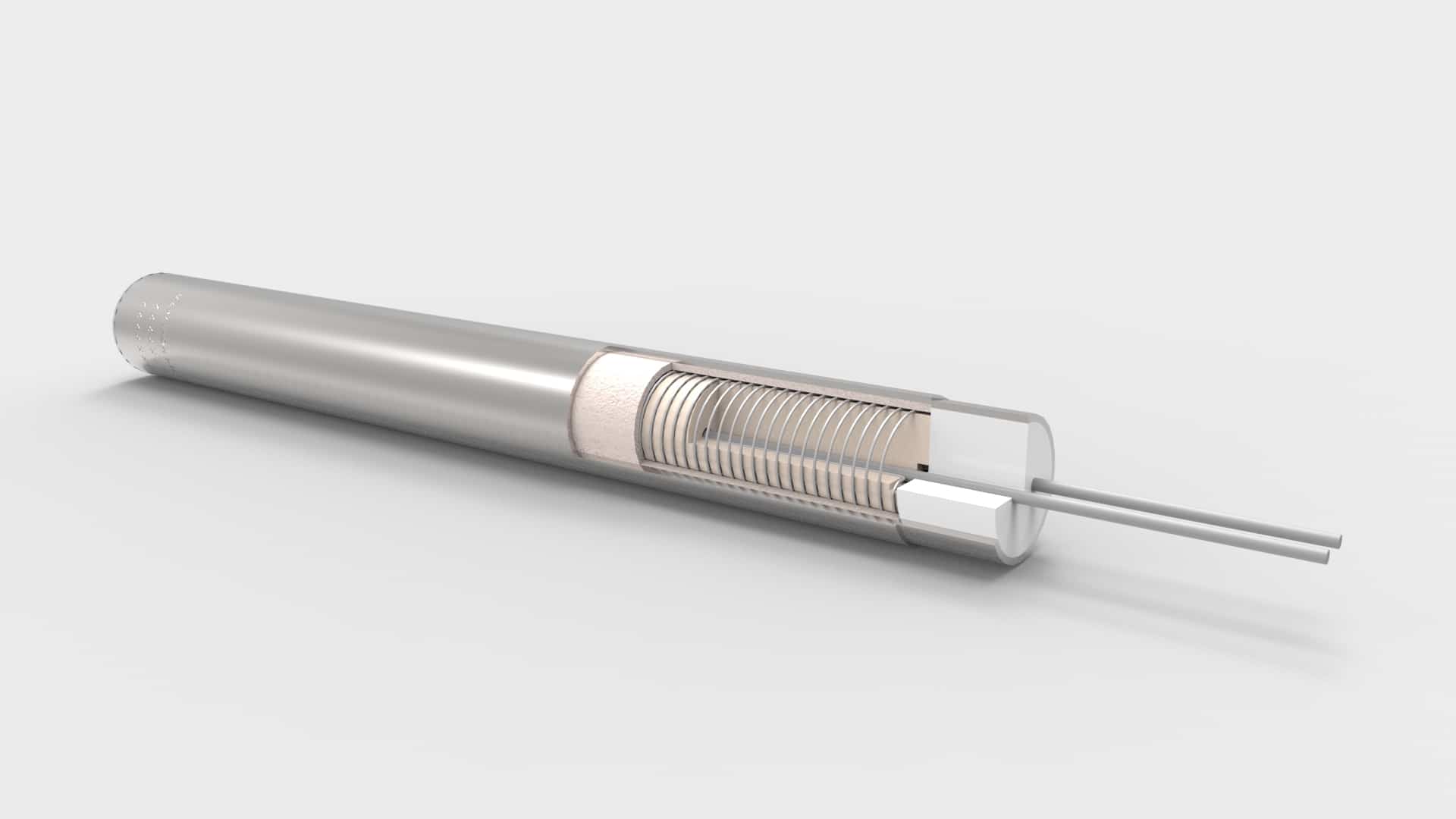

Cartridge heater often considered as component heater has a heating coil wounded on a ceramic core and are cylindrical-shaped, heavy-duty Joule heating element. Electricity flows through coil when two or three-phase voltage is applied. The electricity heats the coil and, subsequently, the cartridge sheath. The watt density (in Watt/inch²) depends on the number of spirals or turns per inch. The sheath comes in contact with the surface being heated. Insulation in the cartridge heater ensures that the heating wire never comes in contact with the sheath and protects the sheath from melting in case of any mishap. The leads that come out of the heater terminal have metal conduit, or silicon sleeves to protect from high temperature. Lead wires are often fiberglass or silicon rubber.

These heaters provide a suitable, reliable and competent method of applying concentrated heat to solid metal components to high temperatures, particularly where compact, insert type heating is desirable. Swaged construction provides minimal air gaps, which lead to high efficiency and improved heat transfer. Distinguished for long trouble free service, cartridge heaters have precise dimensions and tolerances. Heating elements are kept close to the material being heated for maximum heat transfer, minimum core temperature, and faster heating. Use of stainless steel sheaths provides non oxidizing surfaces. The surface watts density and operating temperature of a cartridge is dependent on hole clearance. The larger the hole clearance the lower the recommended watt density. For temperature sensing, a thermocouple should be positioned in the heater but its life is reduced by slow “ON/OFF” cycling of power controllers. So PID auto tuning controllers with solid state relay or thyristor output are suggested.

TECHNICAL SPECIFICATION:

| Sheath Material | Stainless steel, INCOLOY |

| Watt Density | Up to 400 W/in2 |

| Design temperatures | Up to 760°C (1400° F). |

| Voltage | Up to 480V AC |

| Length | Up to 72 inches |

| Leads | Stranded/ Swaged in/ Pin leads/ Crimped on/ Customized |

| Controls | Thermocouple/ RTD |

| Sheath Length tolerance | ±3% (standard), special tolerance available on request |

| Wattage length | +5%, -10% |

| Resistance tolerance | +10%, -5% |

Note- For custom design requirements please contact sales@marathonheat.com

STANDARD SPECIFICATION:

| Nominal diameter | Minimum diameter | Maximum diameter | Std. Lead wire gauge | Max amps with std. Lead wire | Max lead wire gauge | Maximum amps | Maximum volts |

| 1/8” | 3.022 | 3.14 | 24 | 3.6 | 24 | 3.6 | 240 |

| 1/4″ | 6.19 | 6.32 | 24 | 6 | 22 | 9 | 300 |

| 6 mm | 5.82 | 5.97 | 24 | 6 | 22 | 9 | 300 |

| 6.5 mm | 6.35 | 6.47 | 24 | 6 | 22 | 9 | 300 |

| 5/16” | 7.77 | 7.89 | 24 | 6 | 22 | 9 | 300 |

| 8 mm | 7.84 | 7.97 | 24 | 6 | 22 | 9 | 480 |

| 3/8“ | 9.37 | 9.49 | 22 | 9 | 18 | 15 | 480 |

| 10 mm | 9.86 | 11.96 | 22 | 9 | 18 | 15 | 480 |

| 12 mm | 11.83 | 12.48 | 22 | 9 | 18 | 15 | 480 |

| 12.5 mm | 12.34 | 12.67 | 22 | 9 | 18 | 15 | 480 |

| 1/2″ | 12.55 | 12.97 | 22 | 9 | 18 | 15 | 480 |

| 13 mm | 12.85 | 13.46 | 22 | 9 | 18 | 15 | 480 |

| 17/32” | 13.33 | 15.84 | 22 | 9 | 18 | 15 | 480 |

| 14 mm | 13.84 | 13.97 | 18 | 15 | 14 | 26 | 480 |

| 5/8” | 15.72 | 15.84 | 18 | 15 | 14 | 26 | 480 |

| 16 mm | 15.84 | 15.97 | 18 | 15 | 14 | 26 | 480 |

| 17 mm | 16.84 | 16.96 | 18 | 15 | 14 | 26 | 480 |

| 11/16” | 17.32 | 17.44 | 18 | 15 | 14 | 26 | 480 |

| 19 mm | 18.84 | 18.97 | 18 | 15 | 14 | 26 | 480 |

| 3/4” | 18.89 | 19.02 | 18 | 15 | 14 | 26 | 480 |

| 25 mm | 24.84 | 24.96 | 18 | 15 | 14 | 26 | 480 |

| 1” | 25.24 | 25.37 | 18 | 15 | 14 | 26 | 480 |

Material |

Maximum Operating Temperatures |

Maximum Watt Density |

||

| °F | °C | As mentioned above | W/cm2 | |

| INCOLOY | 1400 | 760 | 400 | 62 |

| Stainless Steel | 1000 | 538 | 400 | 62 |

Lead wire options:

| Wire Type | Temperature Rating | Maximum Recommended Temperature | Comments |

| Ultralead | 250°C | 450°C | Excellent, durable wire, good for high-temperature application |

| Teflon | 250°C | 450°C | Good dielectric strength |

| Silicon Rubber | 250°C | 450°C | Good moisture resistance |

| Braided Silicon rubber | 250°C | 450°C | Inexpensive wire, good for non-abrasive applications. |

| MGT | 250°C | 450°C | Superior high-temperature resistance |

| SJO cord | 94°C | 90°C | Rubber Jacket, resistance to oil and moisture. For use on 3/8” diameter and larger. |

Thermocouple: Cartridge heaters can also accommodate internal thermocouple which helps in controlling temperature of heater more accurately. Thermocouples can be of type “J” or type “K”, grounded or ungrounded, and can be attached at the disc end or middle of the heater. Thermocouple lead wire is 24 gauge unless specified, thermocouple leads are of the same length.

Termination Options:

1. Swaged in Leads

- Swaged in Leads are ideal for application where there is excessive movement or leads are required to bent sharply upon exiting the heater.

- In heaters under 3” long, leads wire goes directly into the core whereas in heaters over 3” long, leads are connected to power pins in unheated section.

- Also remember, if the leads are required to be inserted completely into the hole, they are exposed to the block temperature ( maximum temperature for standard leads is 550°C ).

- Unless otherwise specified, all heaters will be supplied with Swaged in Leads.

2. Right angle Leads

- Right angle leads are ideal for application with tight spaces.

- Leads are covered with a silicon impregnated fiberglass sleeve where they exit the heater.

3. Distributed wattage

- Distributed wattage hotrods( with a higher watt density on the ends rather than the rest of the heater) can be used to compensate for end losses in blocks.

- Distributed wattage hotrods are available in all diameters.

4. Right angle stainless steel conduit

- They offers the same advantages as swaged in stainless steel conduit but allows use in tight spaces.

End Seal options:

1. Teflon Seal

- Teflon seal is used where an effective sealing is required against moisture and oil contamination.

- Teflon lead wire is used in conjunction with Teflon seal to provide an effective barrier.

2. Epoxy Seal

- Epoxy potting forms a good moisture seal with more mechanical strength than a silicon rubber seal.

- Regular Epoxy is rated at 350°F (177°C) and epoxy lite is rated at 600°F (316°C).

3. Silicon Rubber Seal

- High temperature silicon rubber seal in conjunction with silicon rubber lead wires provides an effective moisture seal up to 400°F (200°C).

- It is the most impervious seal of all the other moisture seals.

4. Cement

- Provides protection against some thicker liquids and dust, however it is not waterproof.

- It is also somewhat brittle and subject to cracking in high impact or high vibration application.

- Used for temperatures up to 2600°F (1425°C).

Application |

Sheath Material |

| Molds, Metal dies, Patens, hot plates, sealing tools, fluid heating, aerospace, semiconductor industry, screen exchangers, plastic extruders | Stainless Steel, INCOLOY |

| Food service and medical equipment, Deionized water | Stainless Steel |

| General applications | INCOLOY |

| Highly corrosive applications | Titanium |

- Able to reach and transfer heat wherever required, without losing much energy during the transmission.

- Minimized energy loss and enhanced effectiveness of the heating process.

- Distributed Wattage.

- Higher Watt Densities and Operating Temperatures.

- Temperature sensing capabilities built into the heater can increase its utility and lifespan, by helping to control temperatures and prevent overheating.