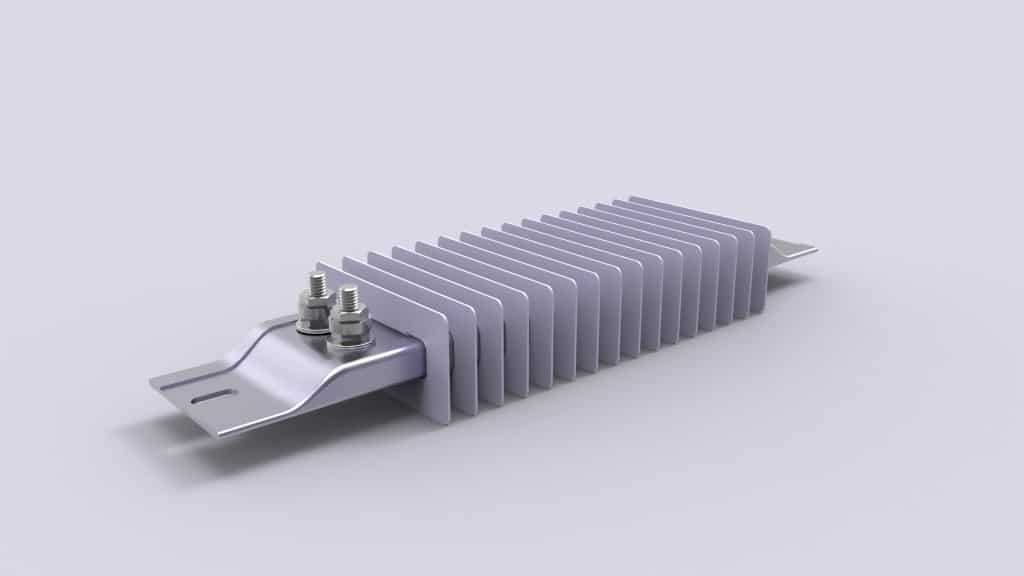

Finned Strip Heater

Finned Strip Heaters are used for both forced and natural convection air heating. It is designed using a helical wound resistance coil placed on a ceramic insulator. Remaining voids are filled with high purity magnesium oxide to increase thermal conductivity and dielectric strength. Continuous spiral fins are permanently furnace brazed to the sheath. Stainless steel rectangular tubing is used to house the heater assembly. It can be easily regulated by using a heating control panel or a thermostat as temperatures can reach as high as 500°F. Lower sheath temperature and element life are all maximized by this finned construction as the fins improve heat transfer in free or forced air heating applications. They can be molded into rectangular, spiral, round or any shape as demanded.

Finned Strip Heater is a flexible and reasonable heating source used across a wide range of applications such as surface heating (platens, dies, molds, tanks, piping); process air heating (drying cabinets, ovens, baking ovens, vacuum dehydrating ovens, moisture protection for motors); dropping resistors for line applications in railroads and load banks; winterizing (hoppers, conveyors, ducts, car heating, thawing); original equipment (air conditioning, laboratory equipment, food packaging, ovens, presses, drying equipment).

Note- For custom design requirements please contact sales@marathonheat.com

TECHNICAL SPECIFICATION:

| Sheath Material | Steel, 304 Stainless steel, Iron, Aluminum, Zinc coated Steel |

| Watt Density | Up to 38 W/inch² |

| Length | Up to 48 inches |

| Fins Material | Aluminum |

- Surface Heating

- Process Air Heating

- Winterizing

- Space Heating

- Food warming

- Packaging and sealing

- Laboratory equipment

- Autoclaves and ovens

- Available with or without mounting tabs.

- Easy and economical to install.

- Corrosion and vibration resistant.

- Durable, versatile and easy to control.

- Uniform Heat Distribution.

- Suitable for low to medium temperatures.

- Durable, versatile and easy to use.