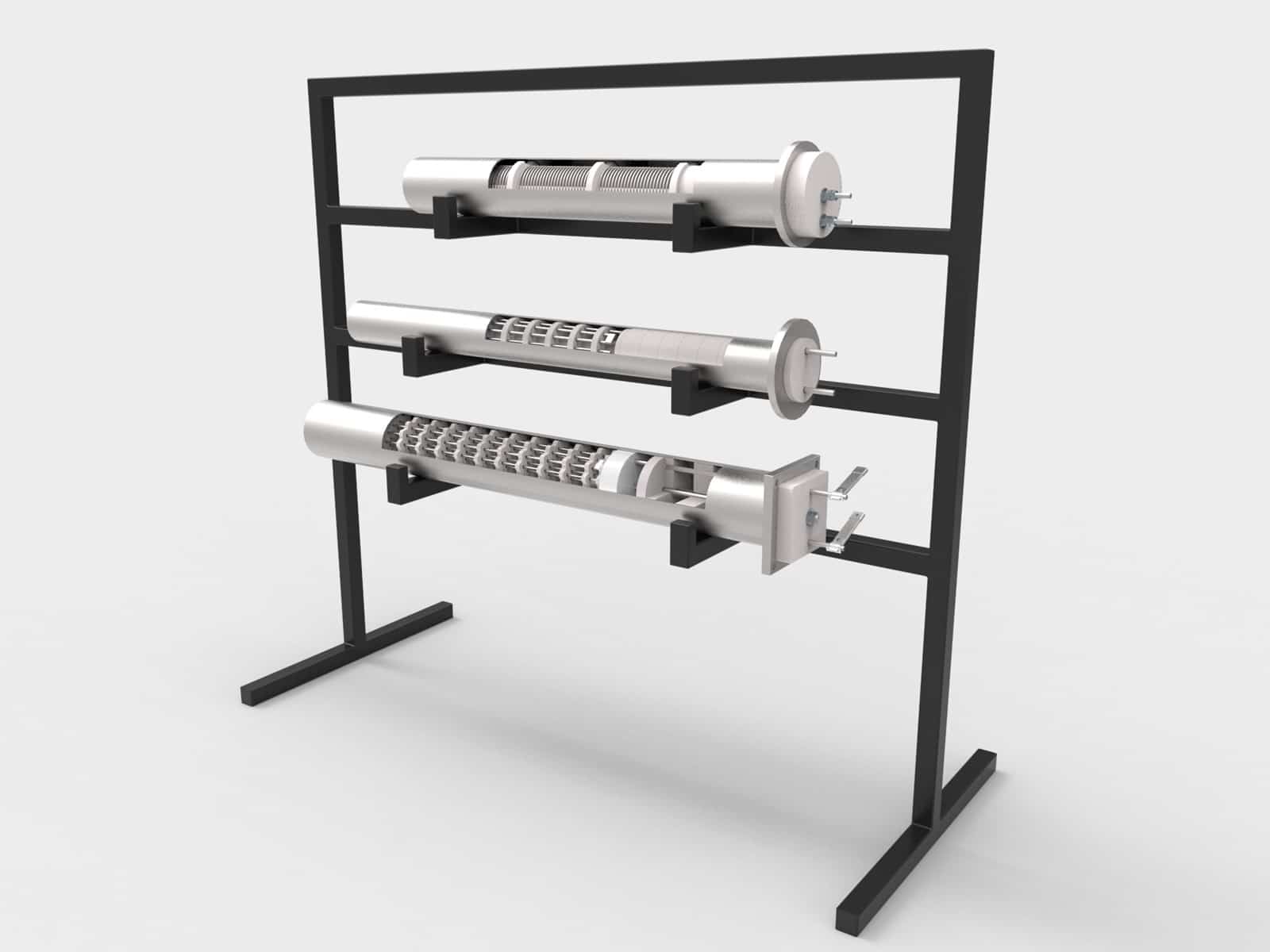

Bundle Rod Heater

Marathon make Bundle rod heater which consists of circular ceramic disc that hold the heating elements. In combination with the radiant tubes which delivers high power, avoid refractory corrosion and avoid the gas impurity in process materials. These design for long life and maintenance free operation. The element can be provided in ferritic alloys up to 1250° C and NiCr alloy up to 1100°C materials.

COMPONENTS OF BUNDLE ROD HEATERS

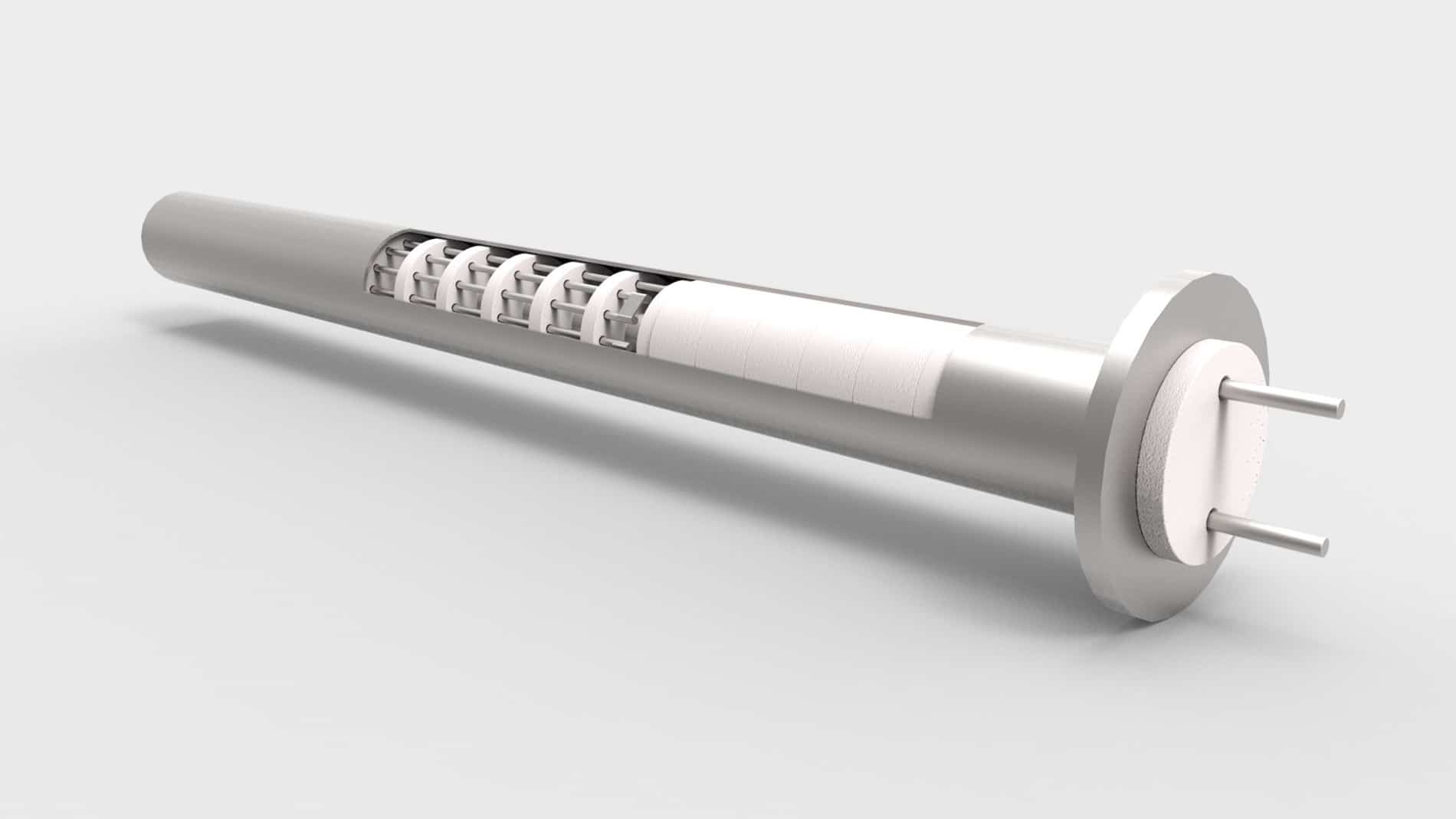

- Terminal Rod: Carries the power supply wiring. Usually made of SS 310 or INCOLOY. Number of rods depend upon the supply connection.

- Center Rod: Used to provide central support to the heater. Usually made of SS 310 or INCOLOY. It is longer than the terminal rods.

- Ceramic Disc: Used to encompass all the heating elements to form a bundle. Made of Alumina. Usually of flower shape.

- Fiber Disc: Used to hold the terminal rods and central rod together. Inserted in the cold zone of the heater. Made of ceramic fiber.

Note- For custom design requirements please contact sales@marathonheat.com

TECHNICAL SPECIFICATION:

| Heating Element Material | Ferritic alloy powder metallurgical element , Mara FeCrAl, NiCr 80/20 |

| Power | 1 kW to 75 kW |

| Cold Resistance Tolerance | ≤3% |

| Max. Temperature | up to 1250 ° C |

| Heater Parameter | Customizable Power Rating, Voltage, Resistance, Length, Diameter |

| Voltage | 240 or 480 V AC |

| Watt density | 1 to 10 W/cm² |

| Radiant Tube | Stainless steel SS grade, Incoloy, PMD, Cast alloys |

| Thickness of Tube | 1.5 to 8mm |

| Length of Tube | 300 to 5000mm (customizable diameter & length) |

| Hangers | Mara FeCrAl, NiCr 80/20 |

| Flange | MS, SS grade |

| Thermocouple Pocket | Alumina Tube(ceramic) |

| Control | Thermocouple, RTD’s, Thermostat for temperature controlling |

| Ceramic disc shape | Flower design, round type, conical type |

- Primary aluminium holding and melting furnace.

- Galvanizing furnace in steel industries.

- Heat treatment furnace in automotive industries.

- Annealing furnace.

- Carburizing furnace.

- Reduces CO2 emissions by eliminating flue gases and controllable various heat treatment furnace, to avoid the contact of burning outcome or to avoid the corrosion of furnace gas to heating element.

- The control of temperature, assemblance and maintenance are very convenient and can be easy to seal.

- Strong heating ability and high efficiency.

- Horizontal or vertical mounting.

- Minimized environmental impact.

- Longer working life and better technical properties.

- Higher surface load & resistivity.

- Free from oxide debris.

- Economical cost with High watt density output.