Constant Wattage Parallel Heat Tracing Cable

Parallel circuit Heating cables are constant watt arrangement designed to put out a certain amount of wattage per linear foot of cable. These are generally constructed of two #12AWG polymer insulated parallel bus wires with a nickel alloy heating element wire wrapped alternatively along the insulated bus wires. These connections are made at the ‘NODE’ point where the nickel-alloy heating element is either welded or connected by rivets. The entire element assembly is then dielectrically insulated with an additional polymer jacket. The power output per unit length is constant, regardless of the overall length of the heating unit. The parallel arrangement preserves systems integrity i.e. if any section of cable should fail, the rest of the heater will continue to operate. Ideally suited for applications where a particular watt density is required at all times such as freeze protection and many

other low temperature process control applications

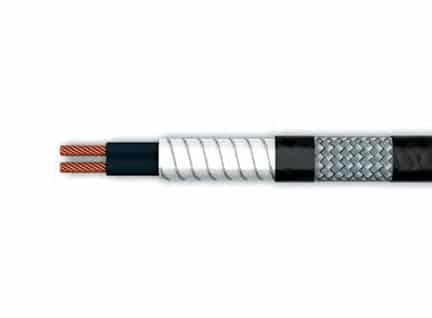

Construction

1. Bus wires

2. Bus Wire Insulation

3. Heating wire

4. Braiding

5. Outer Jacket

Construction Data

| Buswire size | 2X AWG 18 to AWG 15 Stranded Nickel Plated Copper |

| Heating elements | PTFE |

| Insulation | Nichrome |

| Braiding | Nickel Plated copper Braided |

| Outjacket | PTFE |

Maximum Circuit Length(M)

| Voltage – 230 VAC | |||

| Model | Nominal output W/m | Circuit Load | Max. Circuit Length (Meter) |

| CWPHT | 20 | 0.086956522 | 184 |

| 30 | 0.130434783 | 123 | |

| 40 | 0.173913043 | 115 | |

| 50 | 0.217391304 | 92 | |

| 60 | 0.260869565 | 77 | |

| Output wattage at 10°C | 20, 30, 40, 50, 60 W/M |

| Braiding covering area | Over 85% |

| Surface temperature | 200°C |

| Max. exposure temperature | 230°C |

| Min.installation temp. | -40°C |

| Cut to Length | Yes |

| Min Bending radius | 25 mm |

| Voltage | 230 V / Customise |

| Insulation | Dark Brown |