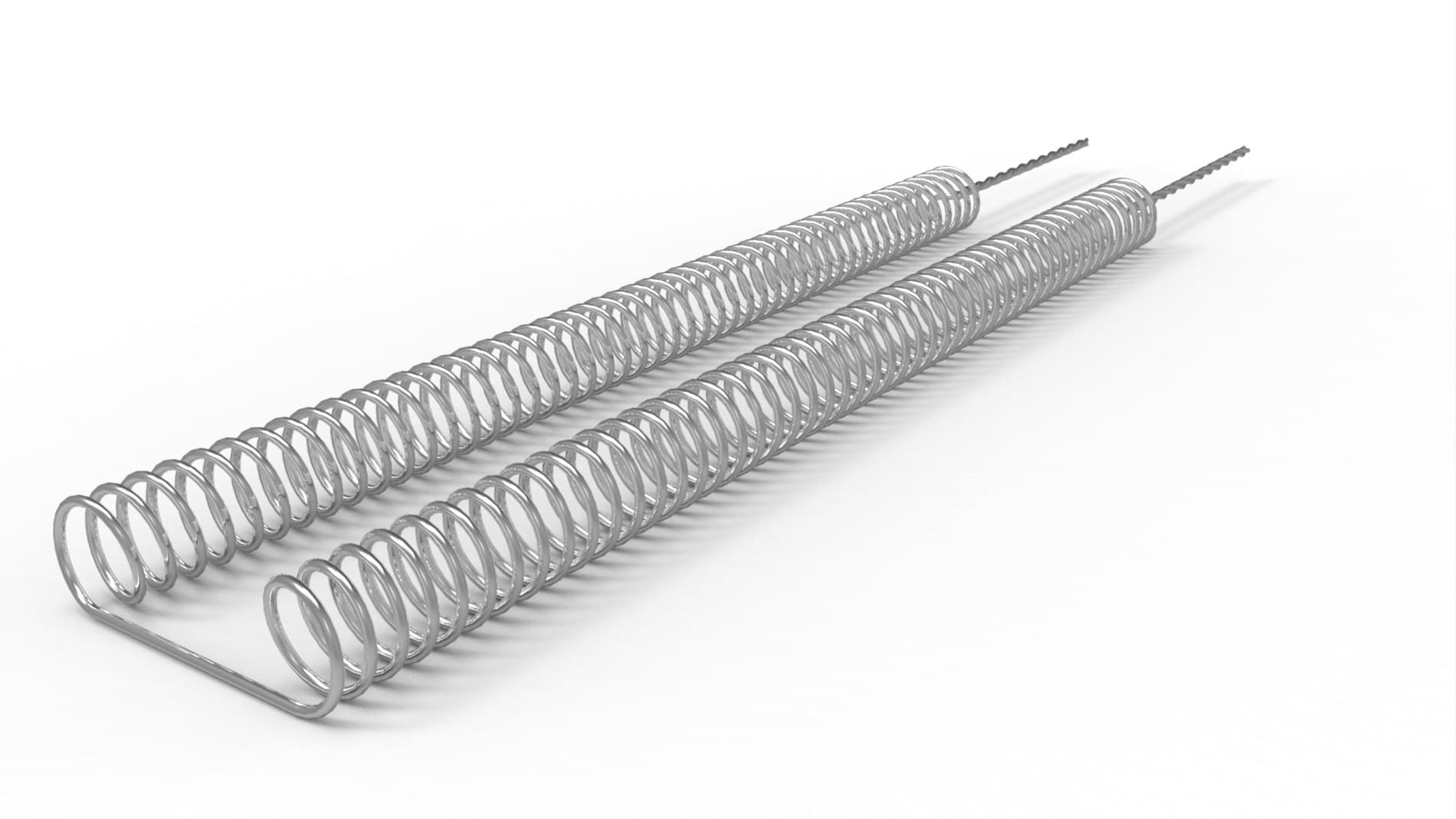

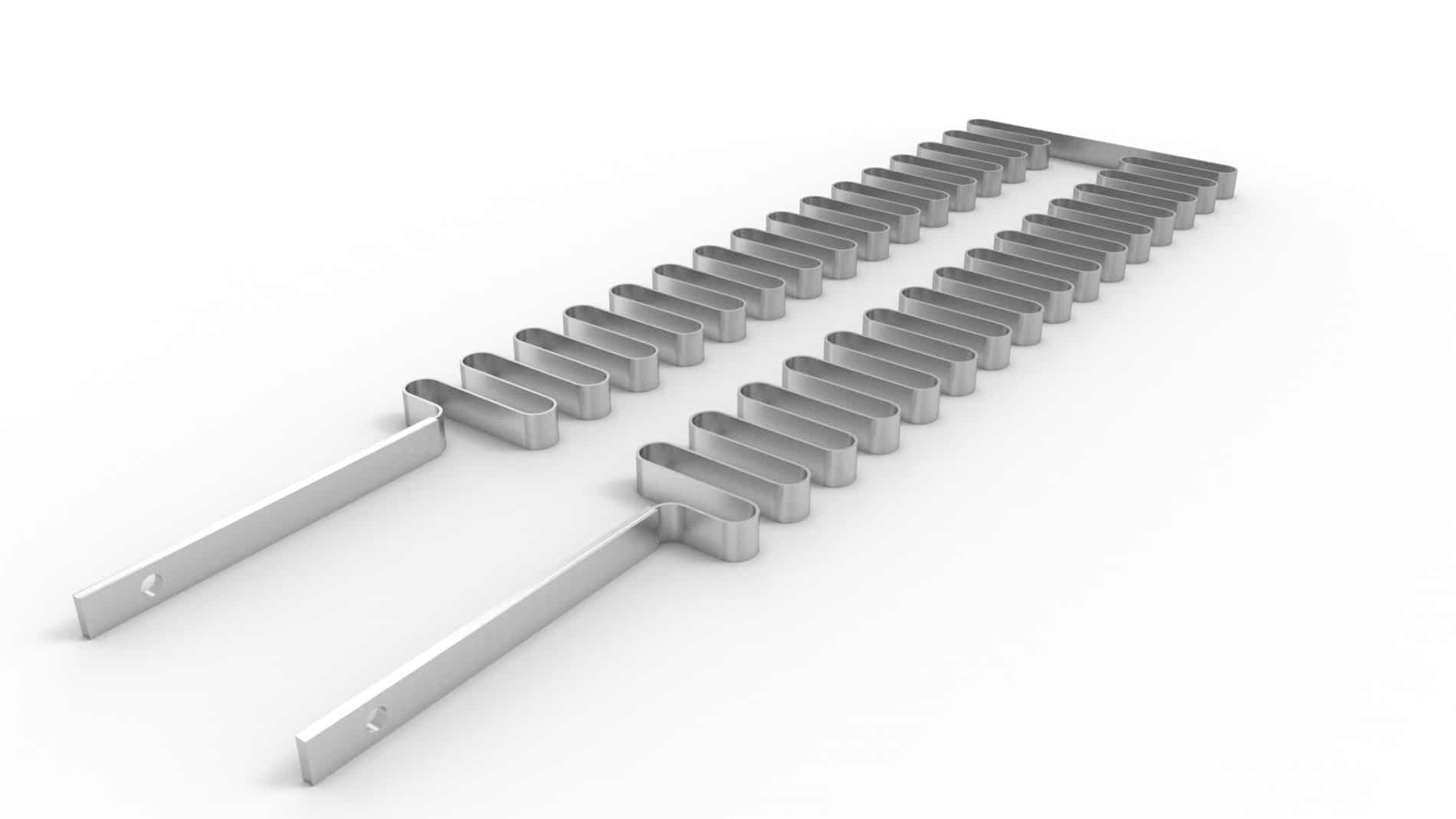

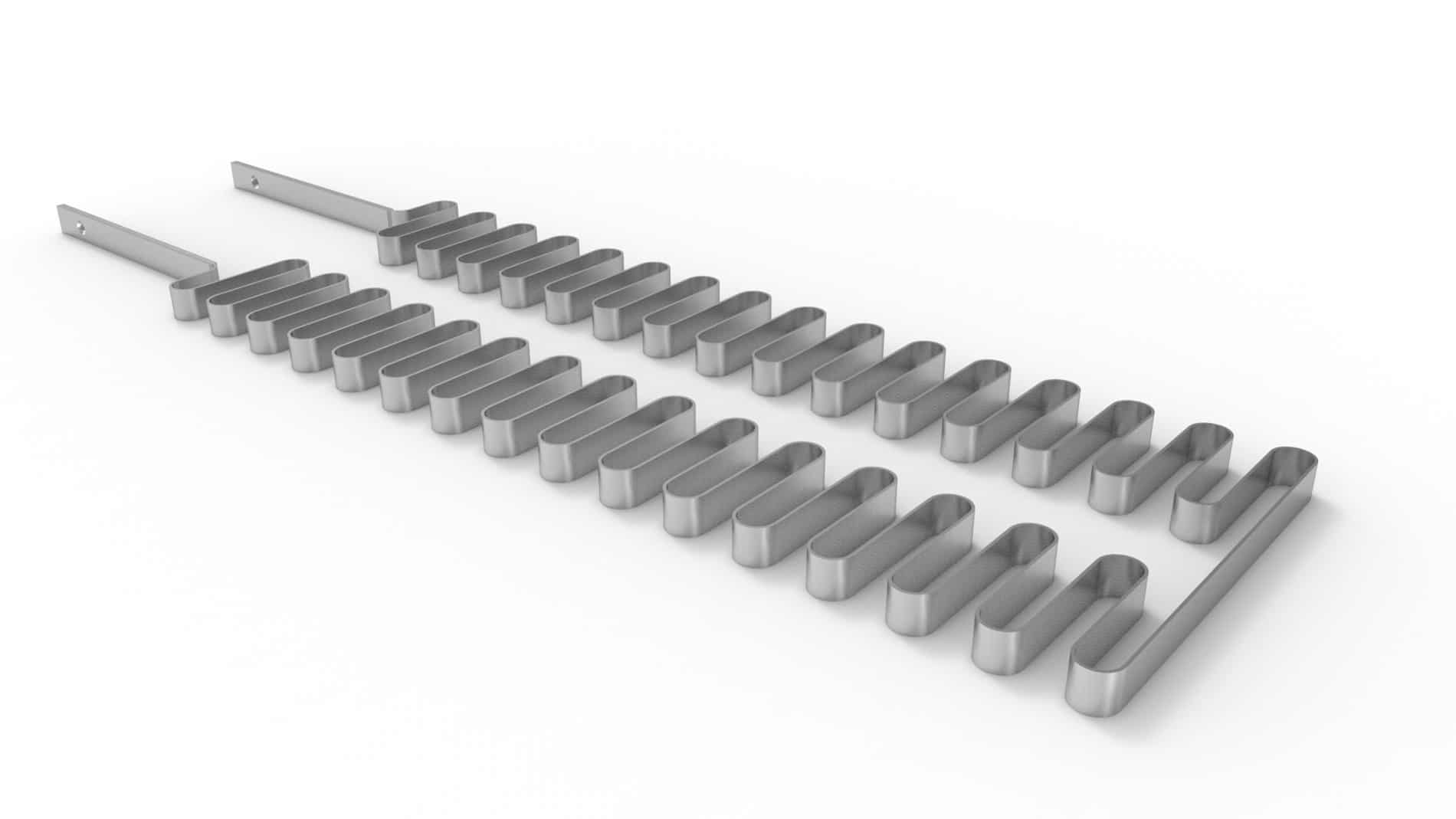

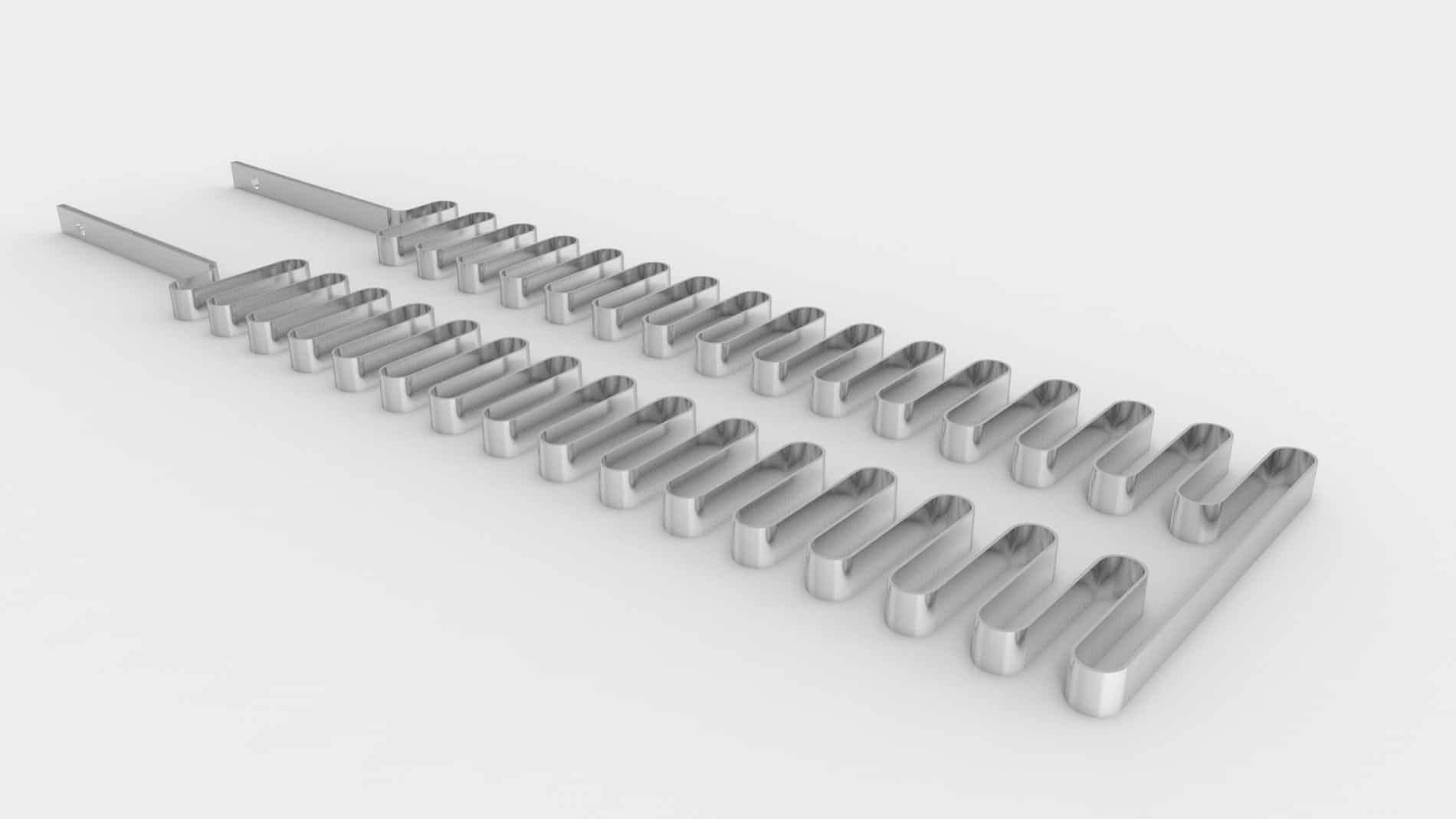

Open Coil Heater

Open coil heating elements have open circuits consisting of coiled resistance wire (usually Ni- Chrome or FeCrAl) fixed onto a supporting element that heats the medium directly. Termed as the most efficient and versatile while also the most economically feasible solution for heating, these elements have fast heat up times that improve efficiency and have been designed for low maintenance and inexpensive replacement parts. When an electrical current is applied to the wire, it gives off heat. The wire is connected to the control panel which regulates the amount of heat provided by the electric heater and fills the tunnel of the air handling unit. Because of the low mass and fast response time, SSR or SCR switching devices are advisable. They serve as an indirect solution to decrease watt density requirements and prevent heat sensitive materials from breaking down. The heater can be formed into a compact, coiled nozzle heater supplying a full 360 degrees of heat with optional distributed wattage.

The face velocity of the air passing over the open coil elements must not be less than a minimum specified value when the heater is energized. There are three factors that are considered when an appropriate face velocity is calculated, i.e. kW, frame size and heater element type. Sufficient airflow for the required kW in a given frame prevents an overheating condition. Heat must be dissipated away from the heating elements.

The following calculation is used for determining face velocity:

Face velocity = CFM/Face Area

Another consideration is the amount of current draw the electric heater will place on the incoming power source. Electric heaters should be divided into individual circuits drawing 48 amps or less. The ‘amp draw’ can be calculated using the kW and voltage of the heater.

Amps = (kW x 1000)/ (Vac x 1.732)

Attention must also be paid to the geographical area in which the open coil heater is to be located.

TECHNICAL SPECIFICATION:

| Heating wire | Nichrome or ferritic alloys FeCrAl |

| Rating | 4 – 20 kW |

| Watt density | Up to 3 W/cm² |

| Operating Temperature | Up to 1100 °C |

| Length | Customizable |

| Outside diameters | Customizable |

| Voltage | 240 or 480V AC |

| Controls | SSR/ SCR/ Relays/ RTD |

| Terminations | Customizable |

- Plastic injection molding nozzles

- Semiconductor manufacturing and wafer processing.

- Hot metal forming dies and punches.

- Sealing and cutting bars.

- Medical, analytical and scientific instruments.

- Restaurants and food processing equipment.

- Cast-in heaters.

- Laminating and printing presses.

- Air heating.

- Textile manufacturing.

- Heating in a vacuum environment.

- High ductility

- Low mass

- Constructed with no open seams.

- Available with fittings for mounting.