Circulation Heater

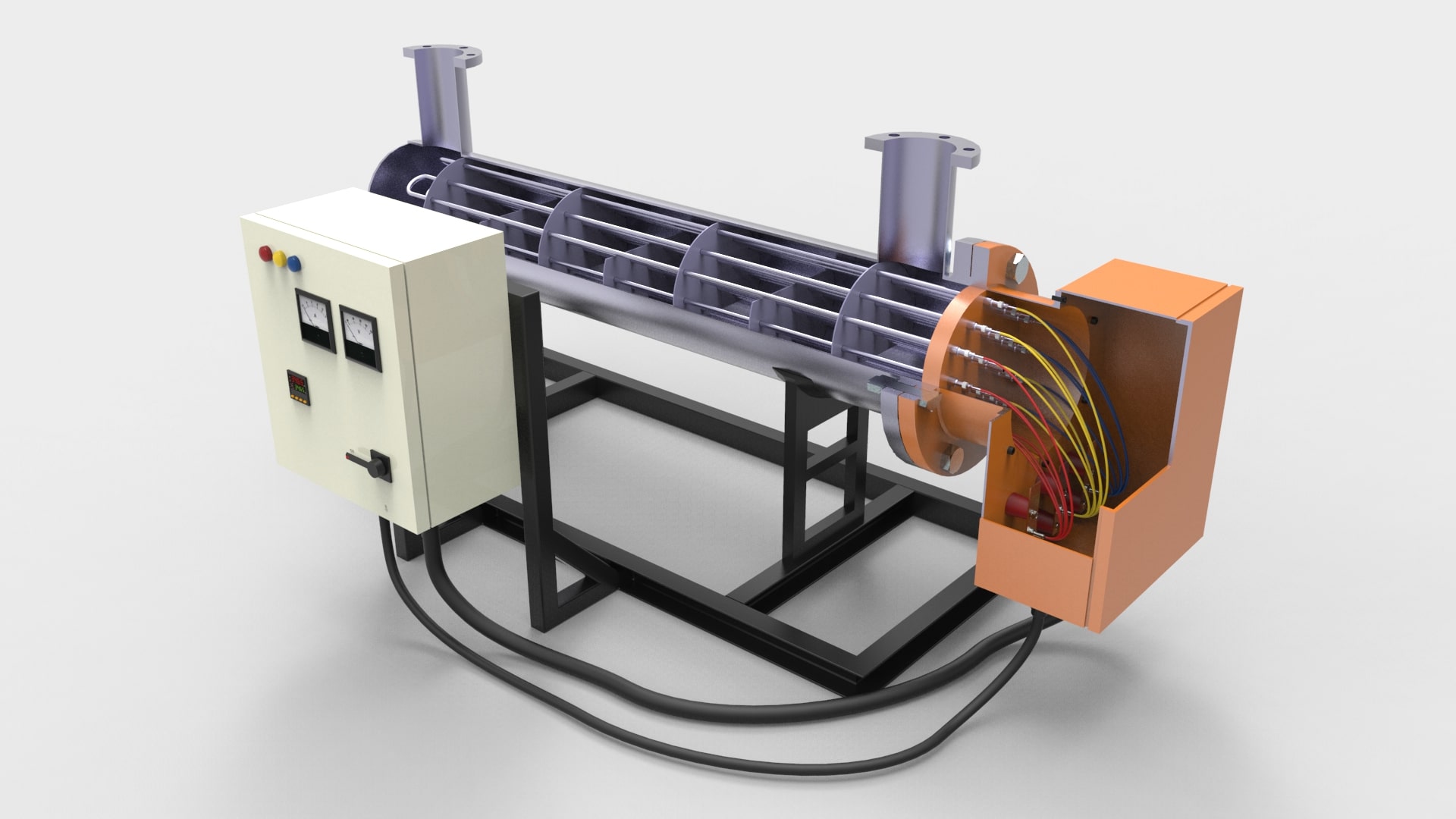

Circulation heater (a.k.a inline heaters) is basically an immersion heater covered by an anti-corrosion metallic vessel chamber. It is accompanied by National Pipe Thread (NPT) screw plug or ANSI flange heater assemblies mated with a pressure vessel. The vessel is mainly used to provide insulation to prevent heat loss in the circulation system. An inlet flange transports the fluid into the circulation system, which is then circulated and heated until the desired temperature is reached. The heating medium will then flow out of the output flange at a fixed flow rate decided by the temperature control mechanism. Since it is a compact heating system, the operation is fast and executed in a short time. The heat generated is evenly distributed and the efficiency of the heater is high. Drain valves are also provided to remove leftover fluids or residues. Temperature sensors can be used with any control to achieve the desired temperature range. To manage the liquid flow rate of the heater, the wattage can be manipulated. When the requirement is such that liquid is to be pumped around anyway, a circulation heater is a logical choice.

Circulation heaters provide a ready-made means to install electric heating with a minimal amount of time and labor. This is accomplished by combining heating elements, vessel, insulation, terminal enclosure, mounting brackets and inlet and outlet connections into a complete assembly. Such kinds of heaters are ideal for processing fluid, including hazardous liquids that require intermediate heating while maintaining viscosity and flow rate, waste oil, steam, gases, and liquids like de-ionized water for use in semiconductor and electronics industries. These heaters are specially used to heat up vegetable oils efficiently, for maintaining viscosity during food manufacturing by indirect heating. For maintaining accurate viscosity, lower watt densities are recommended. Also, no additional terminal box is necessary for this application.

Different alloys and materials can be used to suit specific applications. The table below shows working temperatures and watt densities of variety of materials.

| Sheath Material | Maximum operating temperatures | Maximum Watt Density | ||

| °F | °C | W/in2 | W/cm2 | |

| INCOLOY | 1600 | 870 | 120 | 18.6 |

| 316 stainless steel | 1200 | 650 | 120 | 18.6 |

| Steel | 750 | 400 | 120 | 18.6 |

Note- For custom design requirements please contact sales@marathonheat.com

TECHNICAL SPECIFICATION:

| Sheath Material | Copper, Steel, 316 Stainless steel, INCOLOY |

|

Kilowatt Ratings |

500 KW or higher |

| Wearing Watt density | 6.5 W/in2,15 W/in2, 23 W/in2, 45 W/in2, 65W/in2 |

| Flange & Vessel Material | Carbon steel, Stainless steel |

| Flange size | Up to 42 inches |

| Flange Rating | Up to 2500 lb. pressure class ANSI |

| Terminal Enclosure | IP 23 Standard Terminal Box

IP 66 Water Proof Terminal Box |

| Control | Thermocouple, RTD, Thermostat, Digitally controlled |

| Terminal Enclosure Standoff | 4 or 6 inches |

| Terminal Seals | silicon resin, silicon fluid, RTV, epoxy or hermetic |

| Standard Size | 1.25” NPT Screw Plug size to 14” diameter |

| Flange Gasket | Standard, Spiral wound or any other |

| Thermal Insulation | Standard, High temperature or weather proof jacket |

| Mounting position | Horizontal or Vertical |

APPLICATIONS |

SHEATH MATERIAL |

FLANGE MATERIAL |

| Clean water, hot water storage, portable water, freeze protection of liquid | Copper | Steel |

| Hot water, steam boilers, mildly corrosive solutions (in rinse tanks, spray washers), vapor degreasers | Incoloy | Steel |

| Oils (light or medium), Gases, hydraulic oil, stagnant or heavy oils, lubricating oil, crude asphalt | Steel | Steel |

| Process water, soap and detergent solutions, Boiler and water heaters, deionized water, chemical baths, mildly corrosive solutions | Stainless Steel | Stainless Steel |

| Severe corrosive solutions, demineralized water, food equipment | Incoloy | Stainless Steel |

- Thermal insulation provided to prevent heat loss.

- Mounting lugs provided for support.

- Different terminal enclosures available for easy wiring.

- Digitally controlled for precision.

- Baffles and flange mounting holes provided.

- Easy to install, compact, clean and durable.

- Works in conjunction with control panels.

- Custom designed to meet specifications.

- Highly energy efficient and provide maximum dielectric strength.

- Compatible with standard industry piping and safety standards.

- Gaskets and mounting lugs provided as per specifications.