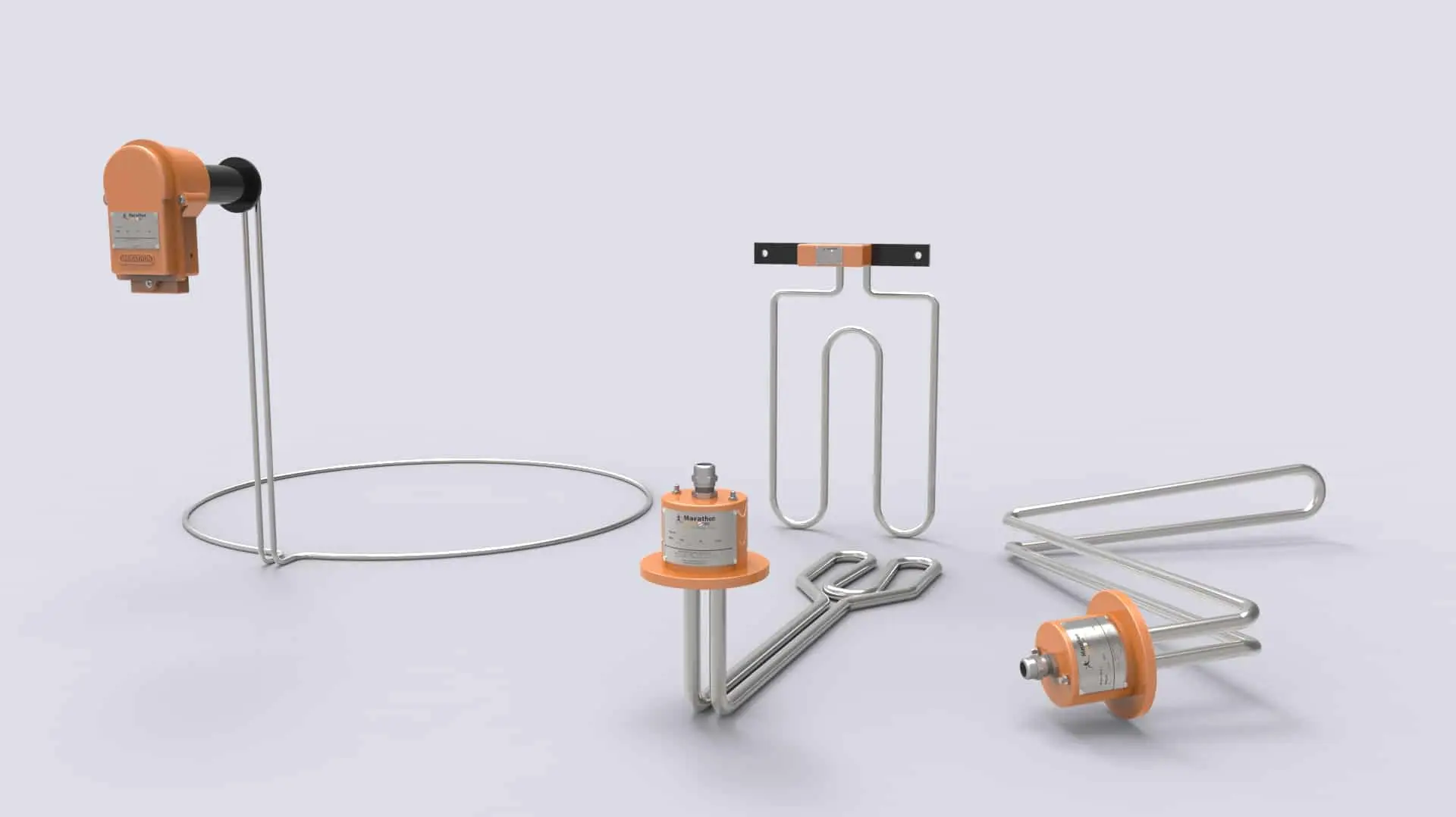

Over The Side Immersion Heater

Over the side immersion Heaters are specially designed for the applications like heating oils of varying viscosities, degreasing solutions, heat transfer oils and caustic solutions, plating baths, salts and acids.

They are portable and can be used where heaters are to be removed without emptying the tanks, or when there is no access to the liquid medium except from the top.

The over the side heater is best suited for the process because the heat transfer is immediate and the temperature can be controlled to the point that no more heat is used than absolutely necessary. They are strong enough to withstand many harsh environments both indoors and outdoors and are an exceptional choice for projects with limited budgets. Application versatility is enhanced with optional sheath materials, kilowatt ratings, terminal enclosures and mounting methods.

Available in various shapes and sizes which fit the customer’s dimensional requirements such as:- “ Installed-from-the-top” ( L or O shaped) which can easily slide into the tank.

The drum immersion heaters are designed for direct immersion in a standard gallon steel drum. Vertical loop immersion heaters are well-suited for open tank applications.

Note- For custom design requirements please contact sales@marathonheat.com

TECHNICAL SPECIFICATION:

| Sheath Material | Steel, 304 Stainless steel, INCOLOY |

| Watt Density | Up to 60 W/in2 |

| Wattage | Up to 50 kW |

| Voltage | Up to 600V AC |

| Sludge Legs | 4 inches |

| Conduit opening size | 1 inch |

| Diameter | 0.315”, 0.375”, 0.430”, 0.475” |

| Terminal Enclosure | IP 23 Standard Terminal Box

IP 66 Water Proof Terminal Box |

| Control | Thermocouple, RTD, Thermostat, Digitally controlled |

- The application for over the side heaters varies greatly from simply water heating or freeze protection to some more complex setup such as viscosity control for oil or wax products that require a steady flow.

- The type of uncommon substances that these heaters are used for include paraffin, solvent, salt or other caustic solutions. The application for paraffin is of a particular interest in heating up the lamination wax.

- One of the difficulties in wax heating for lamination was the use of a conventional heater that couldn’t keep up with the wax requirement for consistent heating and the non-uniformity of wax in the process. Using the over the side heater, the laminating wax can maintain the maximum temperature with a constant viscosity and a uniform thickness of the lamination of wax.

- Another fascinating application involving over the side heaters is solvent degreasing.

- The over the side heater is best suited for the process because the heat transfer is immediate and the temperature can be controlled to the point that no more heat is used than absolutely necessary.

- Rugged and light weight construction.

- Hairpins are re-compressed (re-compacted) which maintains Mgo density and dielectric strength, heat transfer and heater life.

- Integral thermowells, thermostats and thermocouples as per specification.

- Terminal enclosures (moisture resistant, corrosion resistant or explosion proof).

- Portable, durable, easy to install and maintain.

- Sludge legs to keep element above sediments.